Bottling 2017 Vintage

We have been bottling our 2017 vintage! To say we are excited is an understatement!

New Equipment

A friend and fellow wine maker gave us some bottling equipment. He had out grown his small bottler and corker so he let us have them.

This is the bottler. It can fill 6 bottles at one time. It is definitely faster than our old way of siphoning one bottle at a time!

This is the new corker. It is very easy to use. You just put the bottle on the little shelf, press the foot lever and it corks the bottle.

The corking station could keep up with the bottling station very easily.

Old Equipment

They might be small for him but they are a huge step up for us. They sure beat our hand corker and siphon hose that we used to use in our kitchen!

This old corker (our first corker) has been with us for a very long time. It will always have a special place in the barn.

Wines that We Bottled

We started with our white varieties, Moscato and Roussanne. Both of which are semi-sweet. We have smaller quantities of both of them than our reds and we wanted to make sure everything went smoothly. It made sense to start with those two.

As you can see, these pictures were not taken at the time of bottling. We wanted to get some pretty pictures with the labels on the bottles.

We finished with our reds, Montepulciano and Aglianico, they are our dry wines. It was a great time, lots of laughs were had while we worked.

Everything sure did go smoothly! It was amazing how fast and efficent the bottling process went. We felt like a “real” winery!

Step One – Bottling Station

The bottling station. Our bottling line has six filling spouts. Each spout has an automatic shut off for when the bottle gets to the right fullness.

We had a person getting bottles out of the cases and putting them on top of the bottler. Another person was changing out the bottles on the bottler, whenever they would get full and put a fresh bottle in. That brings us to step two!

Step Two – Corking Station

At the corking station, one person would man the corker.

A person from the bottling station would hand the corking person a bottle then the corking person would cork it and hand it to another person who was loading the cases. We had our system down!

The corks needed to be filled from the top. So, as you can see in the picture below, the cork holding compartment is being refilled while the corker is still working.

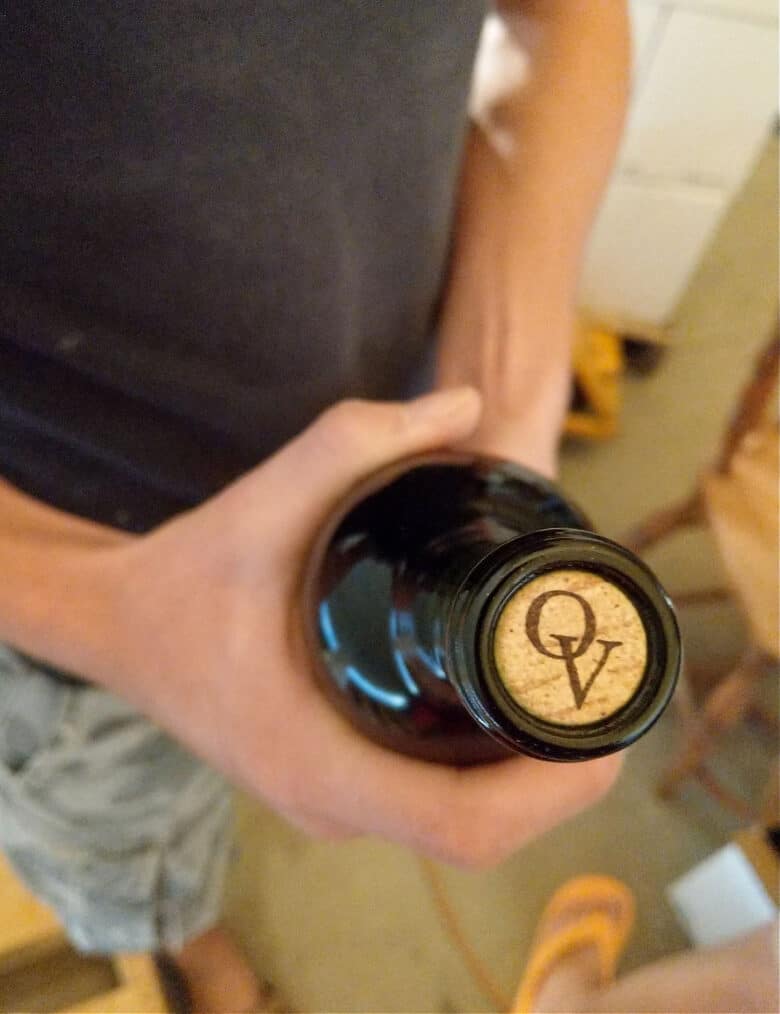

The corks are stamped with our name on the sides and then with out initials on the top. They look so fancy!

Step Three – Loading the Pallet

The final step was loading the pallet with the cases full of wine bottles. This was one of the easier jobs since whoever was doing it got some down time! Great for talking and drinking some coffee.

The baby really enjoyed “helping” hold the boxes down on the pallet!

Bottling 2017 Vintage Success

Bottling the 2017 vintage was a great success. Now we still need to label those bottles but that will come at a later time. Don’t worry, we have marked the cases so we won’t have any mix ups!

Everything sure did go smoothly! It was amazing how fast and efficent the bottling process went. We felt like a “real” winery! With such a successful bottling under our belts, everyone is ready for when we get to bottle again!

For more vineyard posts, check out the links below!